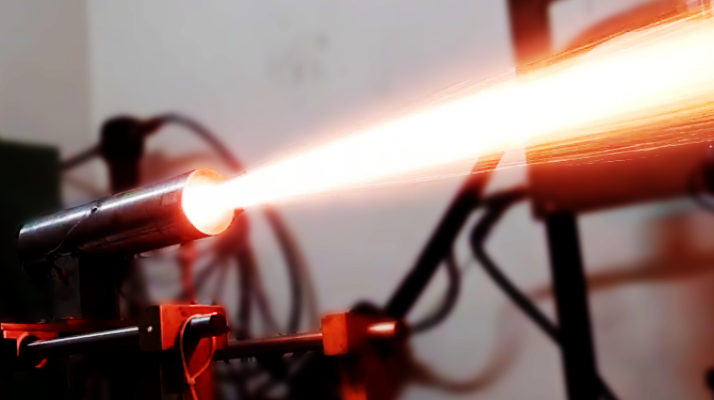

R&M Lab has a dedicated static test setup specifically designed for hybrid rocket evaluation. This testing rig allows for the experimentation with various fuels and oxidizers. The facility makes use of hydrogen peroxide and oxygen as oxidizers, while wax, aluminum-wax blends, and various polymers ae used as fuels . The oxygen setup is capable of handling oxygen flow rates of up to 300 g/s.

An ever-expanding test facility for solid fuel ramjet is available at the R&M Lab. This facility supports tests for upto 4 kg/s air flow rate . This setup has also been upgraded recently to provide vitiated air of temperatures upto 1000 K using hybrid rocket exhaust products and heating elements. Propellants produced in-house have been used for these studies.

The computational facility at R&M Lab currently includes one NVIDIA GPU enabled 26 core machine along with two Intel Core i7 16-core machines and two Intel Core i7 8-core machines . This facility is supplemented by the High Performance Computing Environment - IIT Madras for larger studies.

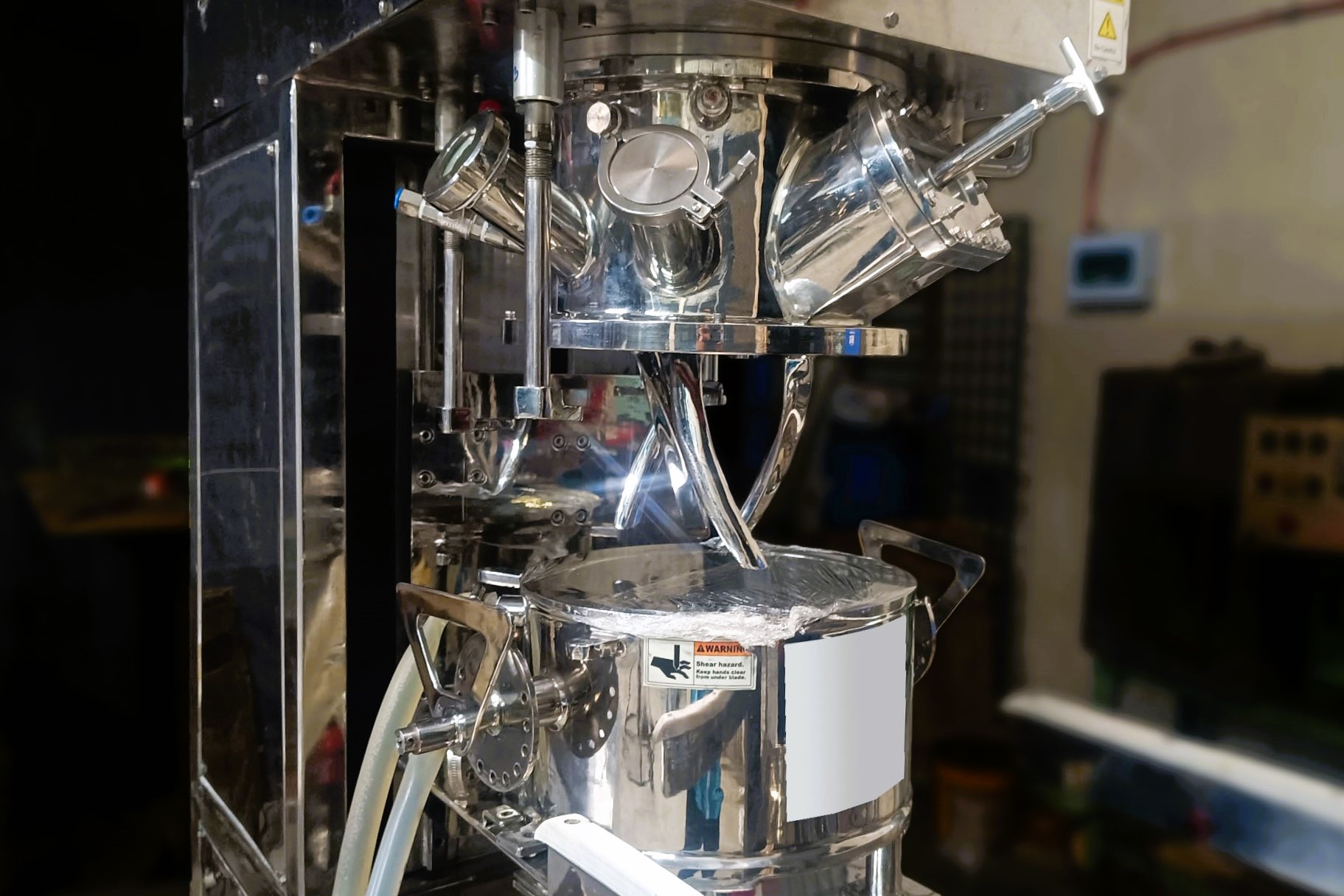

The in-house propellant making facility at R&M Lab allows the production of high quality propellants. The facility has the capability to make propellants by powder pressing and casting. A high degree of homogeneity is achieved by using sigma mixers and gyroscopic mixers.

All lab members are requested to kindly make entries in the following lab-logs while using common lab equipment (authorization required)

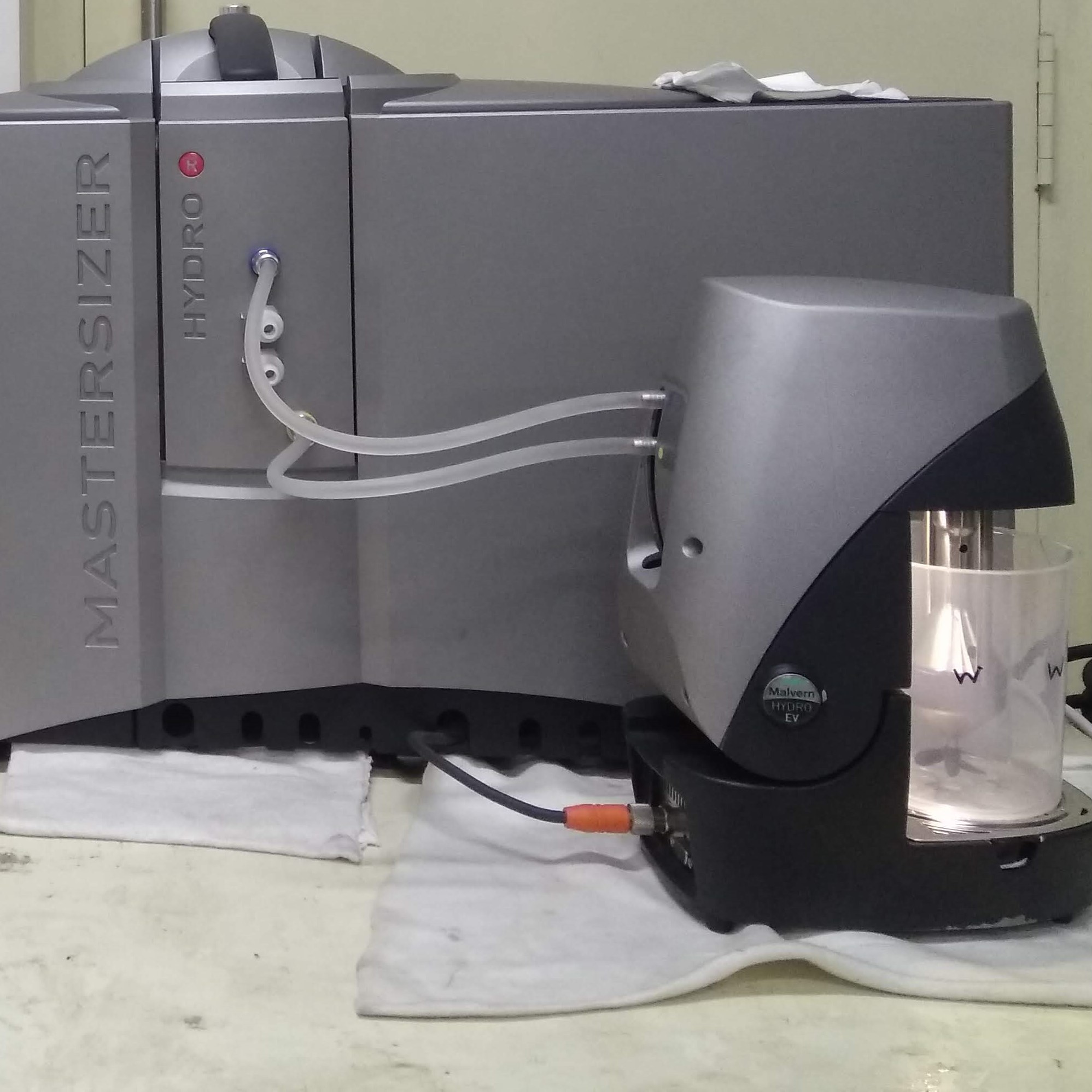

Malven Mastersizer MS3000

This Laser Diffraction based Particle Size Analyzer can measure the particle size from 100nm to 3500mm in powder samples and liquid suspensions.

Hydraulic Press

Hydraulic Presses of 100 Ton & 50 Ton Capacity are available to make pressed propellants and other ingredients from powders.

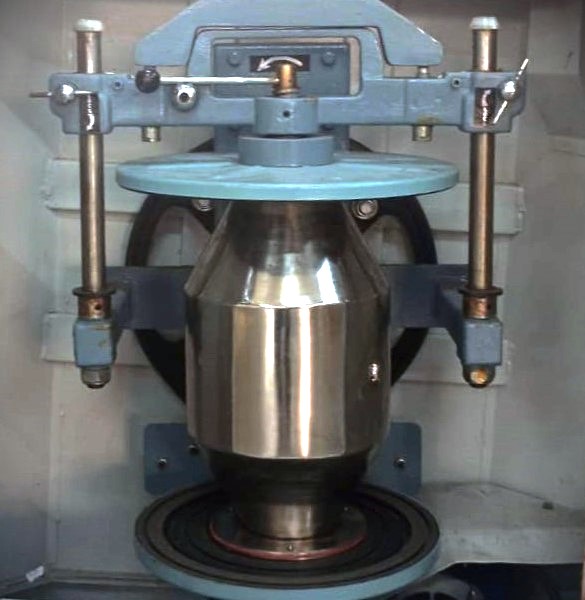

Gyroscopic Mixers

Gyroscopic mixers ranging from capacities of 100gm to 3kg are available at R&M Lab for powder mixing. Even powder mixing is necessary for making pressed propellants.

Crawford Bomb

Our Crawford Bomb is capable of testing propellant burn-rates in highly pressurized environments of upto 350 Bar. Initial temperature sensitivity can also be tested.

Accelerated Aging Chambers

Capable of subjecting propellant samples to isothermal as well as cyclic aging. Humidity controllability of less than 5 % RH can be achieved.